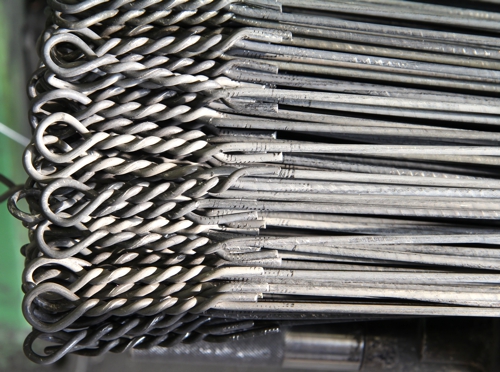

In March our company introduced, in its pickling plant, after the phosphating treatment, the possibility of wire and wire rod covering with polymers lubricant.

We added two tanks to our plant, one for rinsing and counteraction and another one containing polymers; moreover we installed a furnace to speed up the drying process of the product on the wire or wire rod. The whole process has been integrated and automatized with the already existing plant, guaranteeing the supervision and control of every single phase.

Polymers are formed by organic molecules' chains and are free from solvents, heavy metals, mineral oils, carbon disulfide or chloride; they guarantee benefits especially on steel wire by upsetting and cold extrusion.

With polymers usage, you achieve a less usage of the pressing/upsetting machines’ tools, a high lubricant characteristic, removing the usage of stearate cases for skinpass processes and a better finishing on peculiar products.